Constant technological innovation for an excellent result

The willpower to keep up with technological innovation in order to offer our customers a fast and high quality supply service motivates us to constantly invest in cutting-edge machinery that guarantees concrete results in terms of efficiency, speed and precision.

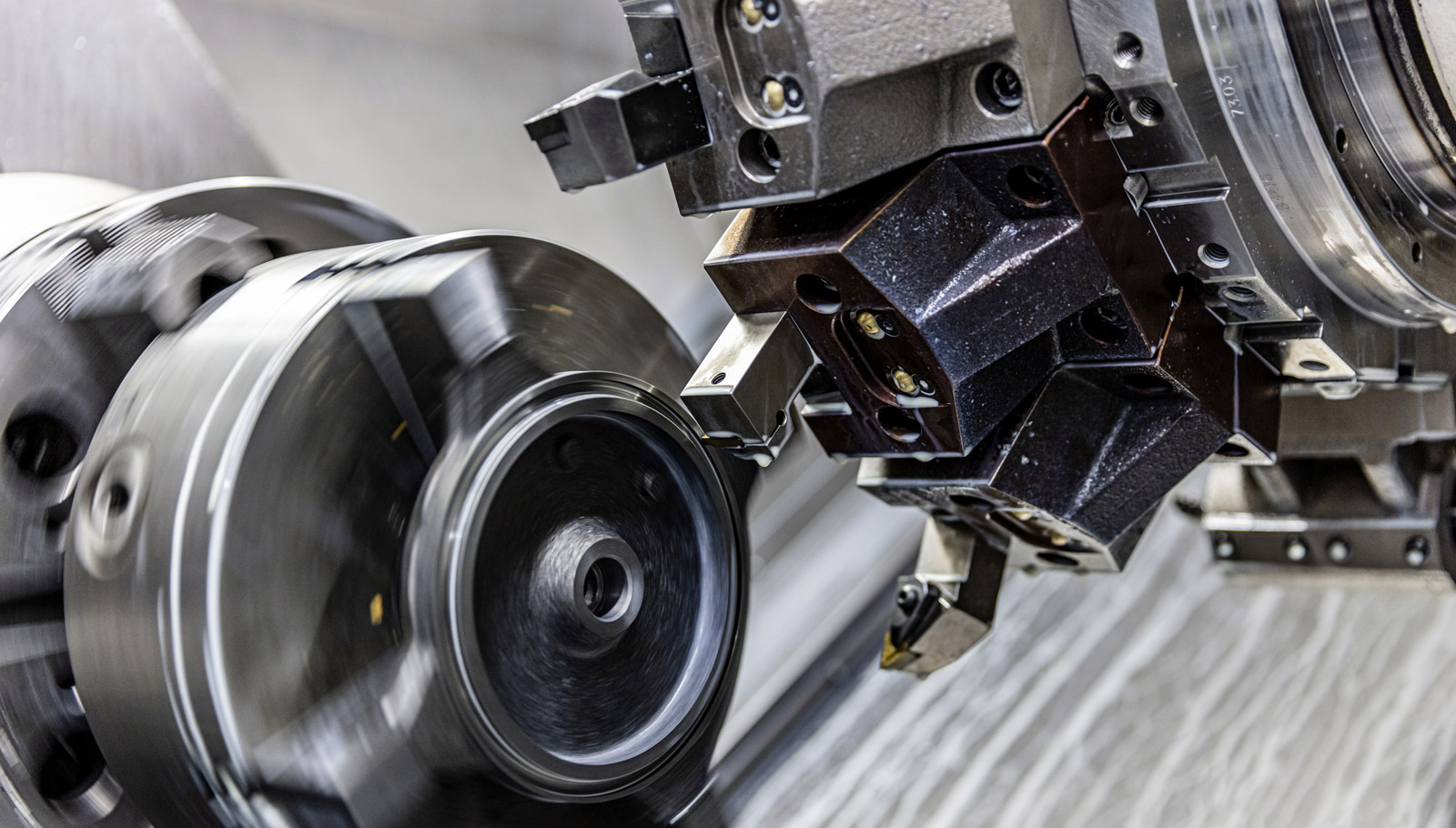

We carry out turning, milling, drilling for components in many materials, such as common steels, alloys, superalloys, non-ferrous metals, plastic materials, with the help of numerical control and traditional machines.

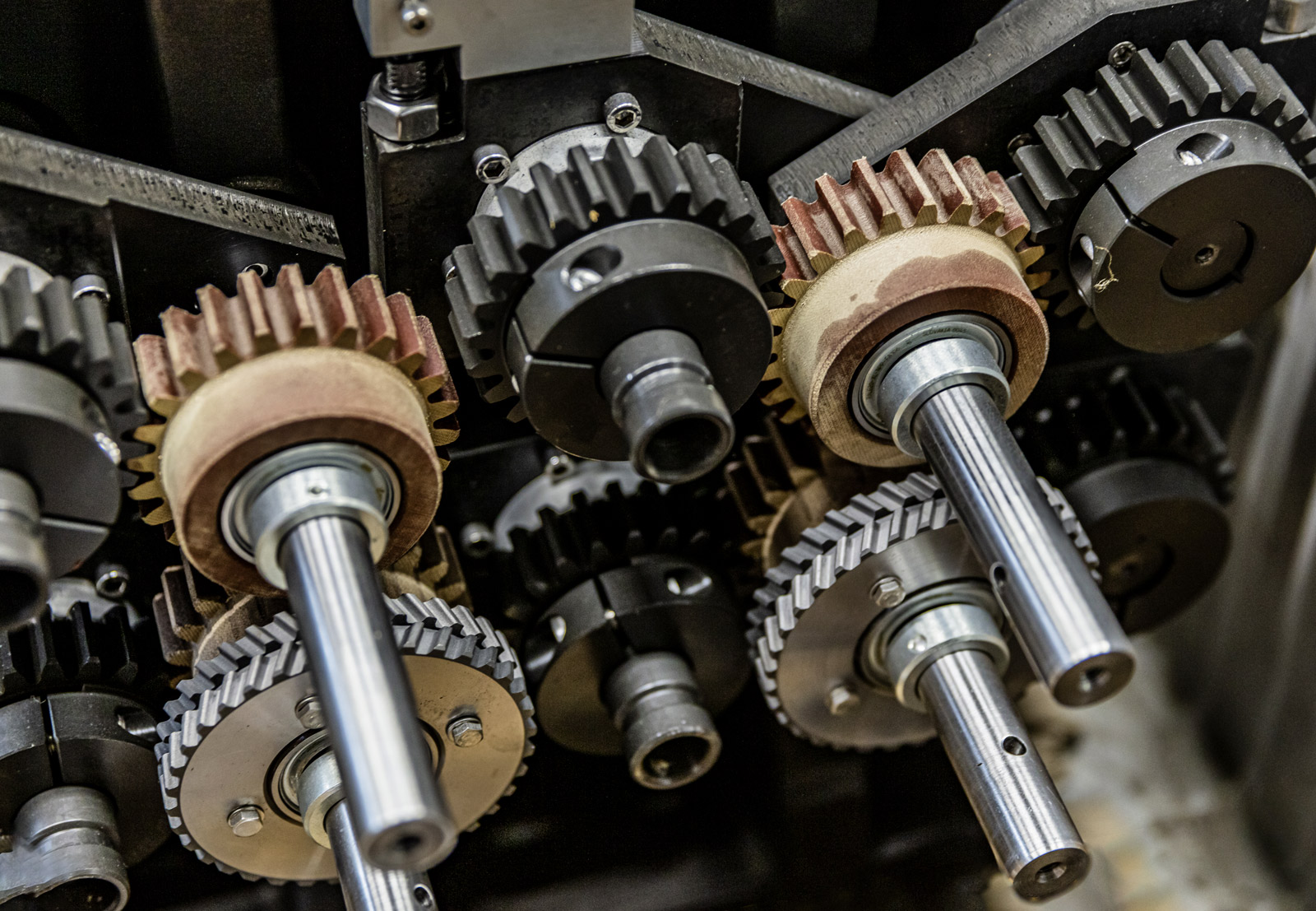

We can also perform surface treatments, such as broaching, toothing and grinding; surface treatments such as chrome plating, galvanizing, nickel plating, phosphate coating and bluing, metallizing, anodizing etc. and heat treatments thanks to the collaboration of qualified and certified partners.

Our machinery fleet is composed by:

- Machining centre DMG Mori Seiki DMU 75 Monoblock 5 axes continuous control 3D Siemens 840 D (Axis X=750mm, Axis Y=650mm, Axis Z=560mm)

- Partner Vantage Topwell TW1480 machining centre with divider (Axis X=1480mm)

- Spinner machining centre VC750 XL version with Siemens CNC (Axis X=630mm Asee Y=530mm Axis Z=465mm)

- Diamond machining centre AVM EV-1020-4 (X-axis X=1020mm Axis Y-axis Y=610mm Axis Z-axis Z=550mm)

- Cnc lathe Biglia 565 (Max. turning diameter 290mm Axis Z=560mm, Axis X=170mm)

- Motorized turning lathe with y-axis mod. B1250Y (Max. turning diameter 680 mm, Axis Z=1195 mm)

- Comev PICO2 CNC lathe (Ø MAX 700 z=2000)

- Motorized CNC Lathe Biglia B 1250 M (Ø MAX 680 z=1195)

- Delta Synthesis 650/400 grinding machine with Diastep 2

- Hexagon Metrology CMM

- Machining centre 5 axis Rema control LEONARD 2.4 T5 (axis X= 2400 mm Y=800 mm Z=800 mm, drowned rotary table D=800 mm)

- Machining centre 5 axis SPINNER U-1530 (axis X=1530 mm Y=530 mm Z=465 mm, rototilting D=650 mm)

- Slotting machine CAM2000