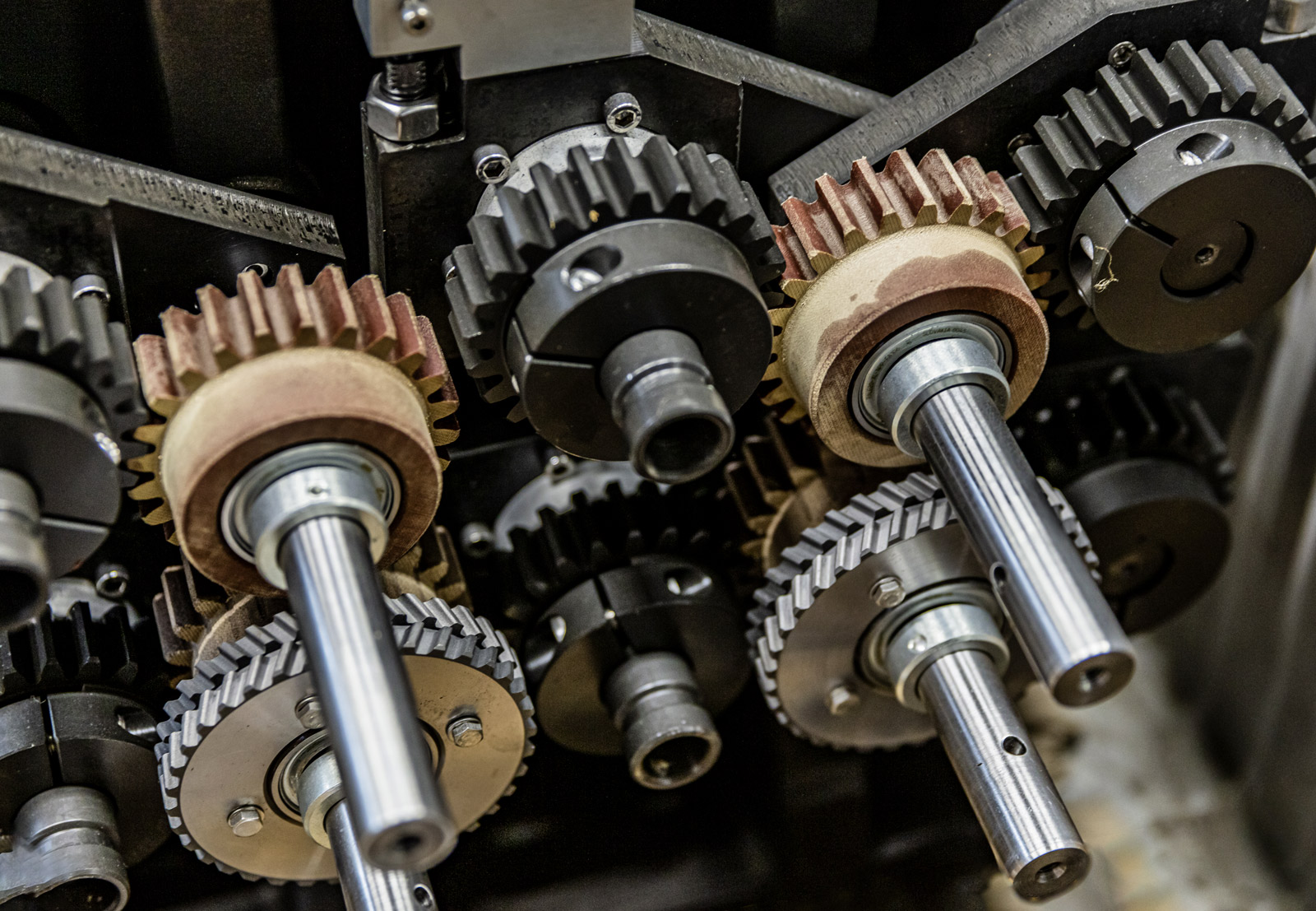

The quality control process is fundamental to offer our customers the guarantee of an impeccable supply at every stage of production.

Our company has 328 calibrated measuring instruments.

- These are divided into:

- Threaded and non-threaded P-NP plug gauges

- Outside centesimal micrometers for a measuring range from 0 to 700

- Digital micrometers 0.001 for a range from 0÷200

- Digital inside micrometers 0.001 for a range from 0÷100

- Bore gauges for 0÷500 range

- Centesimal and millesimal lever and vertical dial gauges

- A wide range of nonius, dial and digital calipers

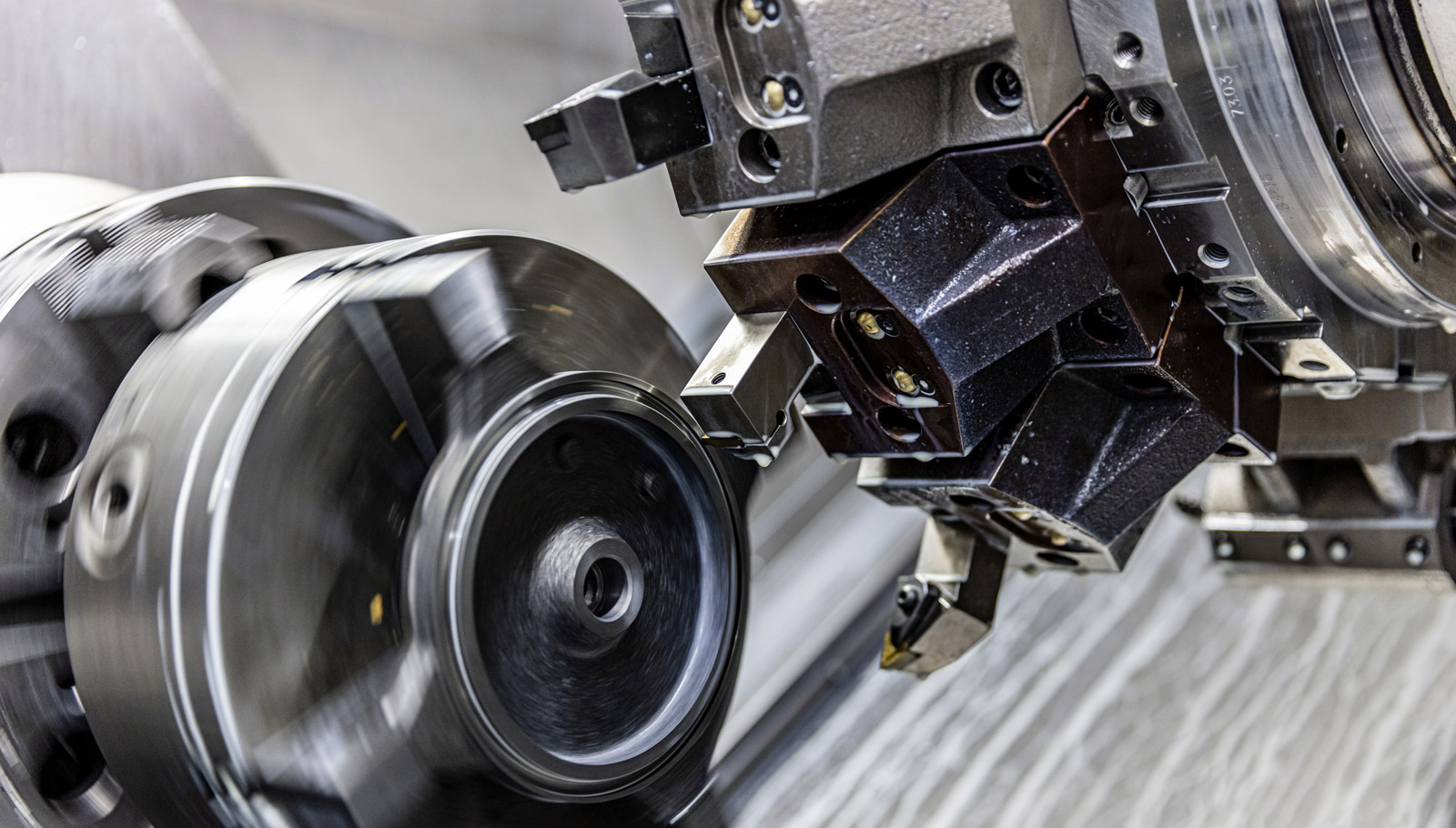

Of particular interest with regard to the technological innovation constantly pursued by our company:

- Digital altimeter 0÷600

- Reset bench 0÷1000

- Hexagon Global S CMM machine

- Mitutoyo Rugosimeter

The entire production is first checked on board the machine on the basis of accurate control plans and then completed in the air-conditioned metrology room, where qualified personnel, with the help of a 3D Global S measuring machine with rotating head and temperature sensor, check dimensions and tolerances and issue detailed reports.

Inside this room, roughness and surface finish are also inspected by means of a rugosimeter.

Our company has obtained ISO 9001:2015 certification, which certifies compliance with quality management standards and the effectiveness of company processes, in order to guarantee all customers an efficient quality management system at every stage of production.